A

B

C

D

Text Solution

Verified by Experts

The correct Answer is:

Similar Questions

Explore conceptually related problems

Recommended Questions

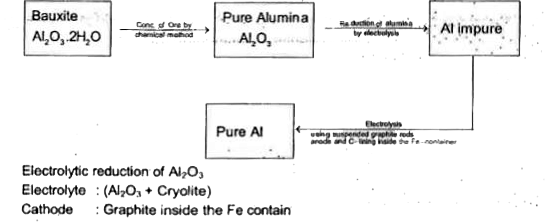

- Extraction of aluminum can be understood by The molten electr...

Text Solution

|

- Extraction of aluminium can be understood by : Electrolytric reduction...

Text Solution

|

- For extraction of sodium from NaCI, the electrolytic mixture NaCI + Na...

Text Solution

|

- Two different electrolytic cells filled with molten Cu(NO(3))(2) a...

Text Solution

|

- One Faraday of electricity is passed through molten Al(2)O(3), aqueous...

Text Solution

|

- Ca, Pb, AI, Na, Mg एवं Cu में से किन-किन धातुओं को विद्युत् अपघटनी विध...

Text Solution

|

- Three faradays of electricity are passed through molten Al2O3 aqueous ...

Text Solution

|

- Extraction of aluminum can be understood by Coke powder is spreaded ov...

Text Solution

|

- অ্যালুমিনিয়াম ধাতুর নিষ্কাশনের সময় গলিত অ্যালুমিনার ওপর কোক-চূর্ণ ছড...

Text Solution

|