First Surface Mirror:

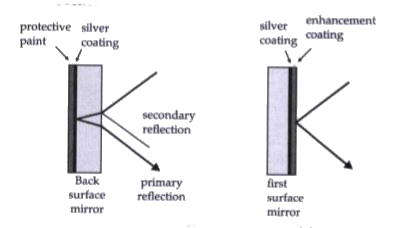

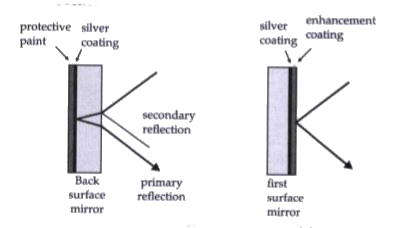

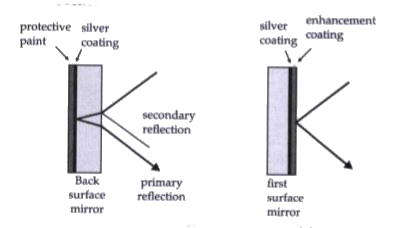

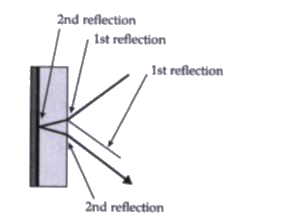

Normally we use back surface mirrors. These are considered low precision mirrors because they actually have two reflecting surfaces. The first reflecting surface is the initial surface on the pane of glass where a small percentage of light is reflected off the surface. The second reflecting surface is the aluminium coating where a high percentage of light is reflected off the surface.

This dual reflection effect of a low precision mirror causes a loss of contrast and image distortion that is undesirable in high precision applications like rear projection systems, scanners and reflecting telescopes. In these cases good image quality is highly preferred, and this is where a front surface mirror is desired for clarity and single image reflection. First surface mirrors are quite common in professional optics. However, compared with back surface mirrors, they have the important disadvantage of being substantially more sensitive. The front surface may be touched, and a metal coating on the front surface is substantially more sensitive than a bare glass surface. For example, fingerprints can easily cause oxidation of the metal. Also, moisture or aggressive gases may cause oxidation of the mirror coating.

Light incident on back surface mirror suffers:

First Surface Mirror:

Normally we use back surface mirrors. These are considered low precision mirrors because they actually have two reflecting surfaces. The first reflecting surface is the initial surface on the pane of glass where a small percentage of light is reflected off the surface. The second reflecting surface is the aluminium coating where a high percentage of light is reflected off the surface.

This dual reflection effect of a low precision mirror causes a loss of contrast and image distortion that is undesirable in high precision applications like rear projection systems, scanners and reflecting telescopes. In these cases good image quality is highly preferred, and this is where a front surface mirror is desired for clarity and single image reflection. First surface mirrors are quite common in professional optics. However, compared with back surface mirrors, they have the important disadvantage of being substantially more sensitive. The front surface may be touched, and a metal coating on the front surface is substantially more sensitive than a bare glass surface. For example, fingerprints can easily cause oxidation of the metal. Also, moisture or aggressive gases may cause oxidation of the mirror coating.

Light incident on back surface mirror suffers:

Normally we use back surface mirrors. These are considered low precision mirrors because they actually have two reflecting surfaces. The first reflecting surface is the initial surface on the pane of glass where a small percentage of light is reflected off the surface. The second reflecting surface is the aluminium coating where a high percentage of light is reflected off the surface.

This dual reflection effect of a low precision mirror causes a loss of contrast and image distortion that is undesirable in high precision applications like rear projection systems, scanners and reflecting telescopes. In these cases good image quality is highly preferred, and this is where a front surface mirror is desired for clarity and single image reflection. First surface mirrors are quite common in professional optics. However, compared with back surface mirrors, they have the important disadvantage of being substantially more sensitive. The front surface may be touched, and a metal coating on the front surface is substantially more sensitive than a bare glass surface. For example, fingerprints can easily cause oxidation of the metal. Also, moisture or aggressive gases may cause oxidation of the mirror coating.

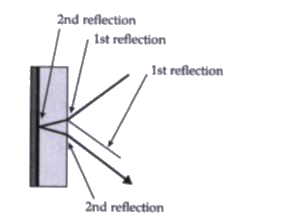

Light incident on back surface mirror suffers:

A

two reflections.

B

one reflection

C

two reflections and two refractions.

D

one refraction and one reflection.

Text Solution

Verified by Experts

The correct Answer is:

C

This dual reflection and refraction effect of a low precision mirror causes a loss of contrast and image distortion.

Similar Questions

Explore conceptually related problems

First Surface Mirror: Normally we use back surface mirrors. These are considered low precision mirrors because they actually have two reflecting surfaces. The first reflecting surface is the initial surface on the pane of glass where a small percentage of light is reflected off the surface. The second reflecting surface is the aluminium coating where a high percentage of light is reflected off the surface. This dual reflection effect of a low precision mirror causes a loss of contrast and image distortion that is undesirable in high precision applications like rear projection systems, scanners and reflecting telescopes. In these cases good image quality is highly preferred, and this is where a front surface mirror is desired for clarity and single image reflection. First surface mirrors are quite common in professional optics. However, compared with back surface mirrors, they have the important disadvantage of being substantially more sensitive. The front surface may be touched, and a metal coating on the front surface is substantially more sensitive than a bare glass surface. For example, fingerprints can easily cause oxidation of the metal. Also, moisture or aggressive gases may cause oxidation of the mirror coating. Precision of back surface mirrors is:

First Surface Mirror: Normally we use back surface mirrors. These are considered low precision mirrors because they actually have two reflecting surfaces. The first reflecting surface is the initial surface on the pane of glass where a small percentage of light is reflected off the surface. The second reflecting surface is the aluminium coating where a high percentage of light is reflected off the surface. This dual reflection effect of a low precision mirror causes a loss of contrast and image distortion that is undesirable in high precision applications like rear projection systems, scanners and reflecting telescopes. In these cases good image quality is highly preferred, and this is where a front surface mirror is desired for clarity and single image reflection. First surface mirrors are quite common in professional optics. However, compared with back surface mirrors, they have the important disadvantage of being substantially more sensitive. The front surface may be touched, and a metal coating on the front surface is substantially more sensitive than a bare glass surface. For example, fingerprints can easily cause oxidation of the metal. Also, moisture or aggressive gases may cause oxidation of the mirror coating. The front surface coating:

First Surface Mirror: Normally we use back surface mirrors. These are considered low precision mirrors because they actually have two reflecting surfaces. The first reflecting surface is the initial surface on the pane of glass where a small percentage of light is reflected off the surface. The second reflecting surface is the aluminium coating where a high percentage of light is reflected off the surface. This dual reflection effect of a low precision mirror causes a loss of contrast and image distortion that is undesirable in high precision applications like rear projection systems, scanners and reflecting telescopes. In these cases good image quality is highly preferred, and this is where a front surface mirror is desired for clarity and single image reflection. First surface mirrors are quite common in professional optics. However, compared with back surface mirrors, they have the important disadvantage of being substantially more sensitive. The front surface may be touched, and a metal coating on the front surface is substantially more sensitive than a bare glass surface. For example, fingerprints can easily cause oxidation of the metal. Also, moisture or aggressive gases may cause oxidation of the mirror coating. In professional optics:

First Surface Mirror: Normally we use back surface mirrors. These are considered low precision mirrors because they actually have two reflecting surfaces. The first reflecting surface is the initial surface on the pane of glass where a small percentage of light is reflected off the surface. The second reflecting surface is the aluminium coating where a high percentage of light is reflected off the surface. This dual reflection effect of a low precision mirror causes a loss of contrast and image distortion that is undesirable in high precision applications like rear projection systems, scanners and reflecting telescopes. In these cases good image quality is highly preferred, and this is where a front surface mirror is desired for clarity and single image reflection. First surface mirrors are quite common in professional optics. However, compared with back surface mirrors, they have the important disadvantage of being substantially more sensitive. The front surface may be touched, and a metal coating on the front surface is substantially more sensitive than a bare glass surface. For example, fingerprints can easily cause oxidation of the metal. Also, moisture or aggressive gases may cause oxidation of the mirror coating. Image formed of front coated mirror:

When the light is reflected from the surface of the mirror, its speed and wavelength will

When wavefront strikes a reflecting surface.

Reflection Of light and Refraction at plane surface

Reflection from curved surface

Recommended Questions

- First Surface Mirror: Normally we use back surface mirrors. These ar...

Text Solution

|

- When the light is reflected from the surface of the mirror, its speed ...

Text Solution

|

- उत्तल दर्पण का परावर्तक पृष्ठ होता है

Text Solution

|

- If the inner surface of the spherical mirror is reflecting, then it is...

Text Solution

|

- When the light is reflected from the surface of the mirror, its speed ...

Text Solution

|

- Curved mirrors where the reflecting surface is on the bulged side

Text Solution

|

- State which surface of a plane mirror reflects most of the light incid...

Text Solution

|

- The centre of the reflecting surface of a spherical mirror lies on the...

Text Solution

|

- Reflection of light #!#Reflection at plane surfaces #!#Laws of reflect...

Text Solution

|